Dielectric elastomers is a type of electroactive polymer that can undergo large deformation in response to an applied electric field. Unlike shape memory polymers and hydrogels, the electroactive is fast in dielectric elastomers. Moreover, the material is light weight, inexpensive to manufacture, and has goo electromechanical conversion efficiency. When prestretched and sandwiched between two compliant electrodes, a dielectric elastomer membrane can stretch by as much as 160%. Dielectric elastomers ha applications for robotic actuators, artificial limbs as well as energy harvesters. However, the material is highly viscoelastic, which can significantly limit the performance of dielectric elastomers. For example, undesired creep of an electro-actuated membrane can induce electric breakdown and development of the pull-in instability and wrinkling instability. We have been developing methods to characterize the temperature-dependent viscoelastic behavior of dielectric elastomers, as well as numerical methods to study the development of viscoelasticity induced structural instabilities.

Dielectric elastomers is a type of electroactive polymer that can undergo large deformation in response to an applied electric field. Unlike shape memory polymers and hydrogels, the electroactive is fast in dielectric elastomers. Moreover, the material is light weight, inexpensive to manufacture, and has goo electromechanical conversion efficiency. When prestretched and sandwiched between two compliant electrodes, a dielectric elastomer membrane can stretch by as much as 160%. Dielectric elastomers ha applications for robotic actuators, artificial limbs as well as energy harvesters. However, the material is highly viscoelastic, which can significantly limit the performance of dielectric elastomers. For example, undesired creep of an electro-actuated membrane can induce electric breakdown and development of the pull-in instability and wrinkling instability. We have been developing methods to characterize the temperature-dependent viscoelastic behavior of dielectric elastomers, as well as numerical methods to study the development of viscoelasticity induced structural instabilities.

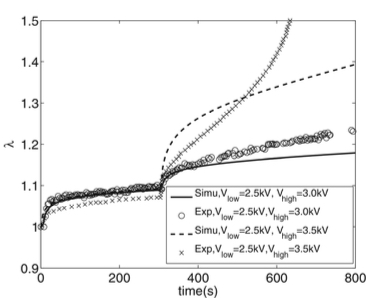

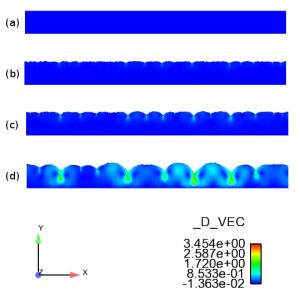

Figure 1: (a) The creep strain of a pre-stretch dielectric elastomer (DE) sheet in response to a step increase in voltage, comparing experiments and a finite deformation viscoelastic model. In experiments, creep at the higher voltage leads to the pull-instability as evidenced by the accelerated creep rate. (b) Finite element simulation from H. Park of crack propagation in a constrained DE film c and (c) creasing in a constrained DE film caused by unstable voltage-induced creep.

Collaborators

- Harold Park, Ph.D., Professor, Department of Mechanical Engineering, Boston University